l ornithine l aspartate tablet

Links

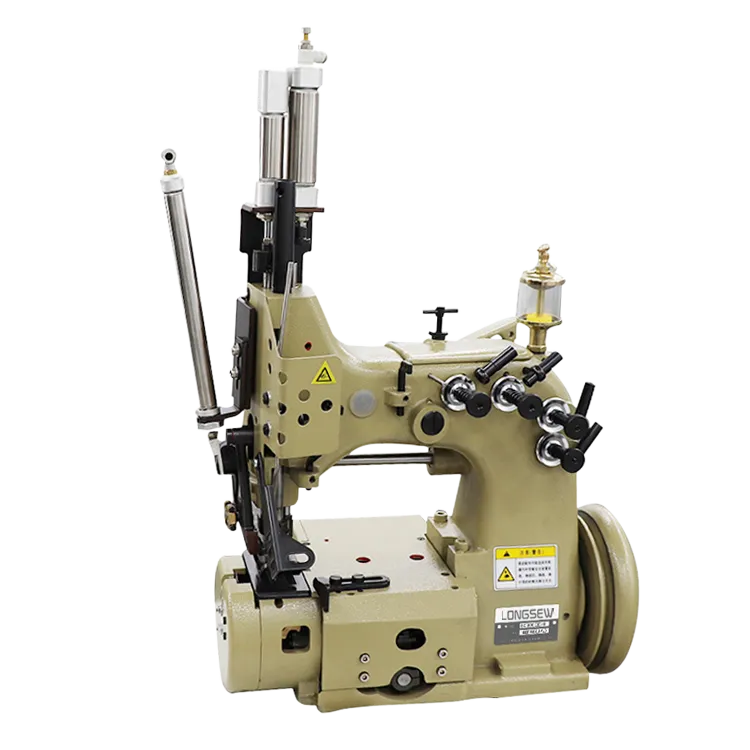

Handheld Sewing Machine vs. Heavy Duty Sewing Machine: Choosing the Best Sewing Machine for Beginners

Conclusion

1. Needle Insertion The process begins with the needle penetrating the fabric, bringing the top thread through the fabric layers.

3. Sewing Technique When you start sewing, proceed slowly to ensure that the fabric feeds evenly under the needles. Keep a steady pace to avoid skipping stitches or causing puckering, especially with elastic or stretch fabrics.

2. Durability Industrial sewing machines are designed to withstand the rigors of daily use. They are built with robust materials and engineering, ensuring longevity and reduced maintenance costs over time. For dedicated home sewists or those who create for a small business, investing in an industrial machine can be economically beneficial in the long run.

Conclusion

Long arm stitching machines also come equipped with advanced features and technology that make sewing and stitching even easier. Many models offer automatic thread cutting, speed control, and needle positioning, as well as programmable stitch patterns and settings. These features help you achieve professional-looking results with minimal effort.

2. Professional Quality The even and parallel lines of stitching produced by a double needle sewing machine enhance the overall appearance of finished projects. This is particularly important for commercial sewing, where the quality of the finish can impact sales and customer satisfaction.

2. Adjust Tension Settings Every fabric type may require different tension settings on your overlock machine. Experiment with tension adjustments on scraps before sewing your main project to achieve the best results.

- Outdoor Gear The robust construction and powerful motor make it perfect for sewing durable outdoor equipment, such as tents and backpacks.

2. Stitching Power For leather sewing, you need a machine capable of handling heavy materials. Look for machines with a robust motor and stitch length adjustment to accommodate different thicknesses of leather.

The construction of these machines typically includes a robust frame, which supports the sewing head and allows for the rapid movement of the needle

. Advanced models are often equipped with features such as automatic thread cutting, needle positioning, and programmable stitch patterns, facilitating greater ease of use and enhancing operational efficiency.5. User-Friendly Features Many modern double needle sewing machines come with advanced features such as automatic needle threading and programmable stitch patterns. These enhancements make it easier for both seasoned tailors and beginners to achieve professional results.

4. Threading the Needles Thread each needle separately, following your machine's threading path. Be careful to ensure that both threads run smoothly and don't tangle. It is often useful to use a lighter thread in the bobbin to avoid visibility issues.

how to use twin needle on sewing machine

In the world of sewing, having the right machine can make all the difference between a frustrating experience and a creative delight. One machine that has garnered significant attention for its versatility and strength is the long arm heavy duty zigzag sewing machine. This powerful tool is designed to meet the needs of both beginners and experienced sewers alike, making it a popular choice for a variety of sewing projects.

Moreover, with the rise of sustainability in fashion, automatic button sewing machines can play a significant role. By enhancing efficiency and reducing waste, they allow businesses to operate more sustainably. For instance, fewer mistakes in button placement mean less fabric scrapping and reduced resource consumption overall. This aligns with the growing consumer demand for eco-friendly production practices, ultimately benefiting the environment.

The modern chain stitch machine also fosters skill development among workers. As these machines often require specialized knowledge and techniques, they encourage training programs that enhance the capabilities of the workforce. This investment in human capital not only improves production outcomes but also contributes to job satisfaction and retention within the industry.

A serger machine, also known as an overlock machine, is designed to stitch and finish the edges of fabric in a single pass. Unlike traditional sewing machines, sergers use multiple threads to create a secured seam and can simultaneously trim excess fabric. This unique functionality not only saves time but also enhances the quality of the final product, making sergers an essential tool for anyone serious about garment construction or fabric crafting.

4. Accessories and Warranty Many zigzag sewing machines come with additional accessories such as presser feet for various needs, bobbins, and instructional manuals. A machine that includes a comprehensive set of accessories may be priced higher, but these extras can add value and convenience. Furthermore, a longer warranty period often correlates with a higher initial price, reflecting the manufacturer’s confidence in their product.

B. Choosing the Right Needles and Thread:

This section will guide readers on selecting the appropriate needles and thread for heavy duty sewing. We’ll explain the different needle types and sizes suitable for various fabrics and demonstrate how to choose the right thread for strong and durable stitches.

Before you begin, it's essential to select the appropriate twin needle for your project. Twin needles come in various sizes and widths, from 1.6mm (2.0mm between needles) to 4.0mm (6.0mm between needles), and can have ballpoint or sharp points depending on the fabric type you are sewing. Ballpoint needles are best for stretch fabrics, while sharp needles work well with woven materials.

Conclusion

In conclusion, the price of the Durby Zig Zag Sewing Machine reflects its robust features, user-friendly design, and overall durability. As it stands, the machine offers an excellent balance of quality and value, making it a worthy investment for both newcomers and experienced sewists alike. By weighing the price against its features and considering the long-term benefits, potential buyers can confidently approach their purchase, paving the way for endless creativity and satisfaction in their sewing endeavors.

The user-friendly design of these machines typically includes easy-to-follow threading paths, automatic needle threading, and adjustable presser feet. Many newer models also feature computerized controls, which enable sewists to select stitches with just the touch of a button. Furthermore, some machines come with additional accessories such as walking feet, quilting feet, and various types of needles, expanding their capabilities even further.

Conclusion

Investing in a heavy-duty home sewing machine is not just about its immediate capabilities; it's also about the longevity it offers. These machines are engineered to last, making them a worthwhile investment for anyone serious about sewing. They require less frequent repairs and maintenance compared to lighter models, allowing you more time to focus on your projects rather than fixing your machine.